Hydraulic Motor Selection Guide

Verify system type for proper pump selection and setup. Regulate oil flow with motor NEEDLE VALVE.

Hydraulic Motors Selection Guide Types Features Applications Engineering360

The application of the hydraulic motor generally dictates the required horsepower and motor speed range although the actual speed and torque required may sometimes be varied while maintaining the required horsepower.

. It was mounted to a gearbox and needed a keyed shaft and SAE 2 or 4-bolt mounting pad. Do not use restrictor orifice or flow limiter Setup Instructions. Up to 190 HP continuous.

Loosen jam nut on motor and back out needle valve 3 or 4 turns counter clockwise. Select motor size closest to tractors hydraulic system capacity. Through using a hydraulic cylinder which converts hydraulic energy into linear motion and work or a hydraulic motor which converts hydraulic energy into rotary motion and work.

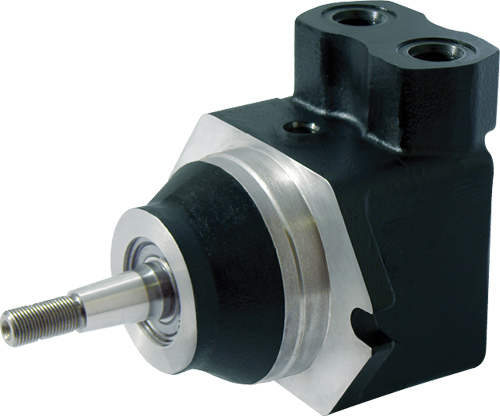

Ad Industrys Trusted Guide For Machinery Parts Supplies Services. A variety of fixed displacement motors ranging from 24 in 3 to 111 in. Low-Speed High TorqueLSHT and High-Speed Low TorqueHSLT.

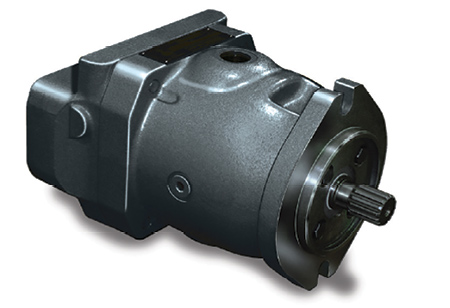

Hydraulic motors are rated by its displacement and torque. An OEM customer needed a motor to spin about 1000 RPM to develop about 40 HP with 40 GPM of hydraulic flow. Deciding which hydraulic motor is right for your application will depend on a number of factors.

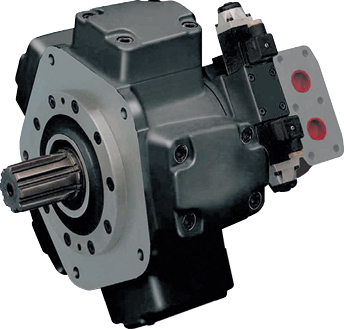

Ad Shop Zoro For Exclusive Offers on Millions of Everyday Products. An axial piston motor uses an axially mounted piston to generate mechanical energy. 57S - 205 lbs.

100 Free to Use. Motor type is the most important consideration when looking for hydraulic motors. Features of the 37- 57 Series 4-Port Motor.

The reservoir plays several important roles. Shut off sprayer boom and agitation valves. The factors that will affect your choice of hydraulic motor.

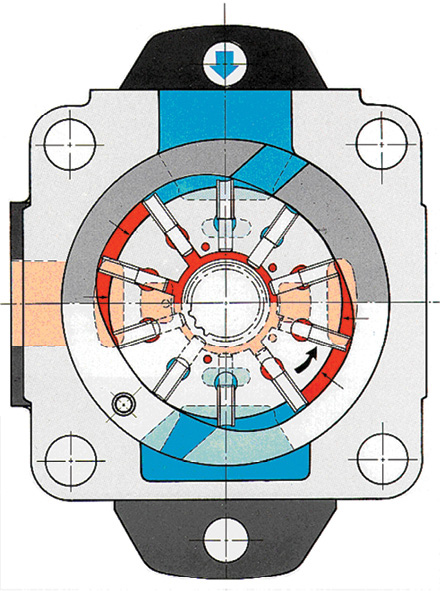

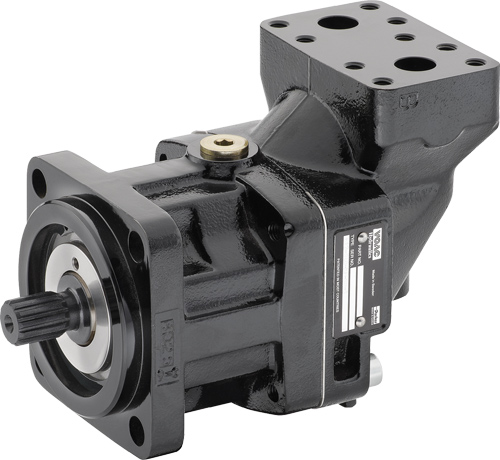

REGULATING HYDRAULIC FLOW TO THE SPRAYER PUMP. We chose a gear motor because it was easily adaptable to the application and available to handle many different flow. The choices include axial piston radial piston internal gear external gear and vane.

Another important element of an industrial hydraulic system is the reservoir. Compatibility with the other components in your hydraulic system. The type of motor selected depends on the required reliability life and performance.

Speeds to 1000 RPM continuous. Paul Badowski August 21st 2017. Starting and stall torques equal to 90-94 of theoretical torque.

Heavy duty pump and motor sizing guide for hydrostatic transmissions Subject. Learn what size of pump or motor is best for your hydrostatic transmission. Shut off sprayer boom and agitation valves.

Ad Get the Hydraulic Motors Mounts You Need. Directional control valves are probably the most common of all hydraulic components and are used to control the starting stopping and reversal of flow in a system. It is then necessary to evaluate the cost of your motor options with the degree of complexity you want for your overall system.

Weight - 37S 171 lbs. Th en it is necessary to evaluate the cost of your motor options along with the degree of complexity you want for the overall system. HYDRAULIC MOTOR CONNECTIONS Inlet marked I Outlet.

Proper hydraulic motor selection starts with the expected performance required by the application then works back to the prime moverthe pump. Characteristics and configurations of manual directional control valves used in hydraulic systems - selecting the right valve for the job. This requires the designer to first match the motor then the pump to a specific system performance expectation.

Eatons full line of hydraulic motors is backed by decades of proven reliability and performance under the toughest conditions and in the harshest environments. Select motor size closest to tractors hydraulic system capacity. 200N Series Motor M Series Motor.

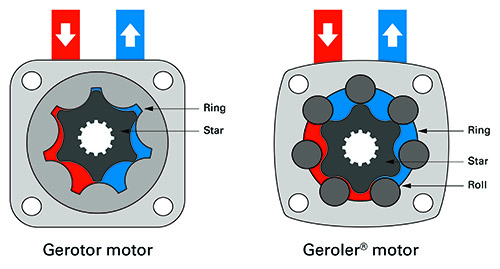

Get total confidence with the efficiency durability safety and speed of affordably priced Eaton GerotorGeroler gear piston and vane motors to fit a wide variety of applications ranging. Duty Cycle or Load Profile It is important to note that these parameters are not independent they are in fact co-dependent and should be. Loosen jam nut on motor and back out needle valve 3 or 4 turns counter clockwise.

Physical characteristics such as robustness weight size etc. Follow the basic formulas as provided on the following page. Ease of service maintenance.

Modified SAE D mounting specification. The reservoir holds a volume of hydraulic fluid. Two-speed operation w external valving.

01 to 1000 revolutions per minute is the speed limit of LSHT motors and 1000 to 5000 revolutions per minute is the speed limit of HSLT motors. Remember that proper hydraulic motor selection starts with the expected performance required by the application then works back to the prime mover the pump. Selecting a Hydraulic Motor.

Proper hydraulic motor selection starts with the expected performance required by the application then works back to the prime moverthe pump. Then it is necessary to evaluate the cost of your motor options along with the degree of complexity you want for the overall system. Shop Northern Tool Now.

A guide to selecting a manual hydraulic directional control valve. Speed and Torque 2. Do not use restrictor orifice or flow limiter Setup Instructions.

Hydraulic motors are classified into two based on its torque and rotational speed. Regulate oil flow with motor NEEDLE VALVE. Hydraulic motor selection The ideal in hydraulic system design is to match overall efficiencies to the application performance expectation.

Hydraulic Motors Selection Guide Types Features Applications Engineering360

Select The Right Motor For Your Hydraulic Applications

Gerotor Motors 5 Selection Tips

Select The Right Motor For Your Hydraulic Applications

Choosing The Right Hydraulic Pump Buying Guides Directindustry

Select The Right Motor For Your Hydraulic Applications

Choosing A Hydraulic Motor For A Medium Speed Application

0 Response to "Hydraulic Motor Selection Guide"

Post a Comment